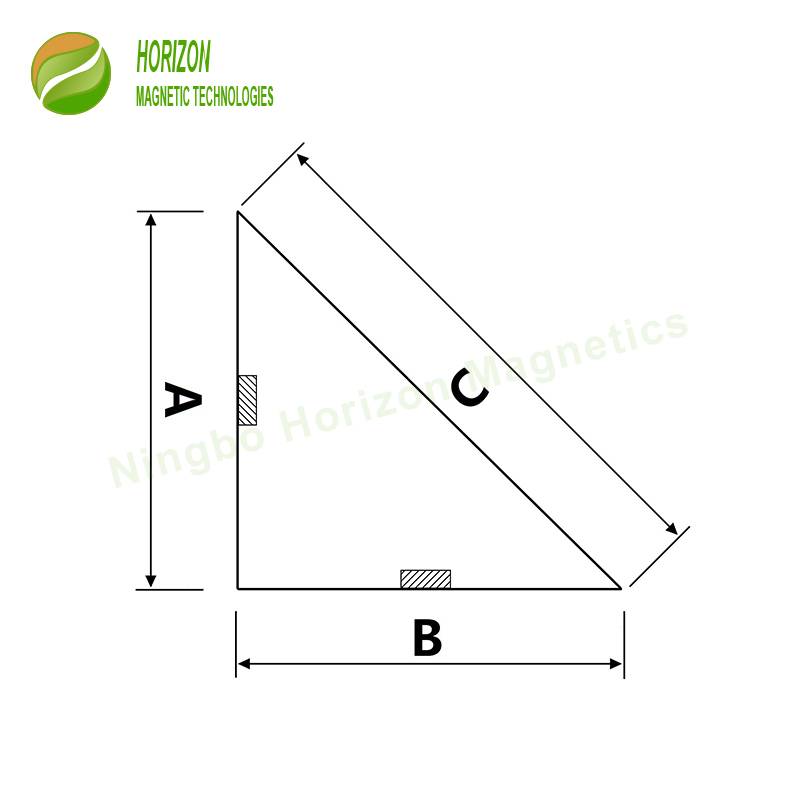

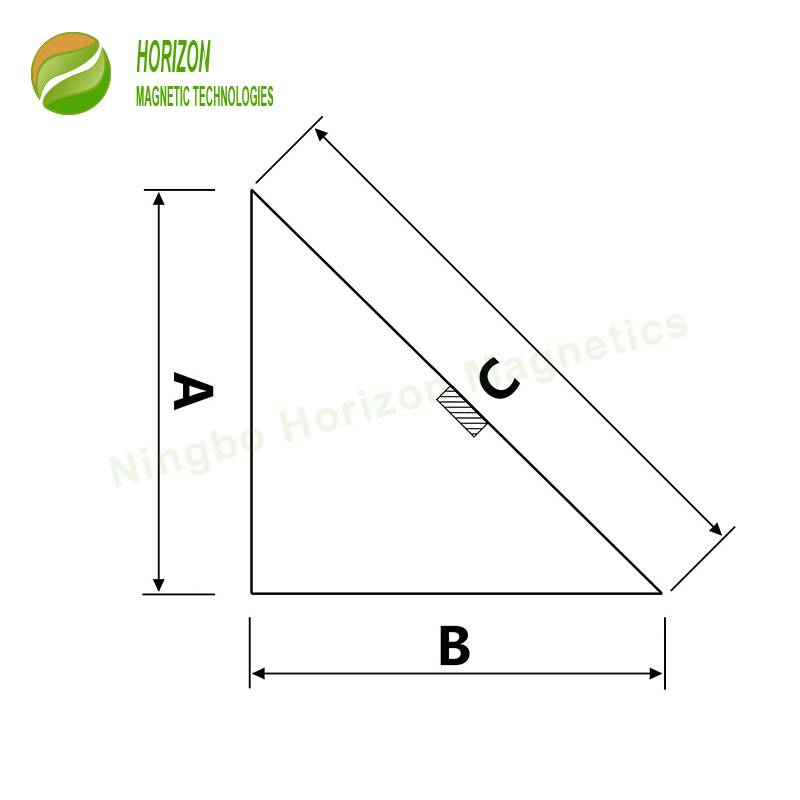

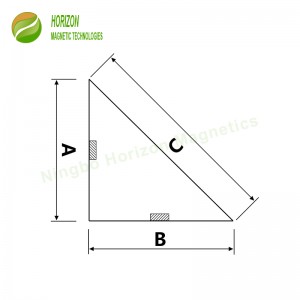

Yakagadzirwa nesimbaNeodymium bar maginetiyakaiswa musimbi yemhando yepamusoro. Sezvakangoita chimiro uye musimboti weNeodymium chiteshi magineti, simbi inodzoreredza iyo polarity yeNeodymium magineti kubva kune rimwe divi kuenda kune rimwe divi rakabatikana rine yakakwirira kubata simba. Uyezve, mazhinji magineti madiki ebhawa anodzivirirwa nesimbi kubva mukukuvadzwa kwemichina. Rutivi rwekusangana runogonesa kukurumidza uye kwakaringana kuiswa kwesimbi chamfer musimbi formwork kuvaka pasina kutsvedza kana kutsvedza. Iyo magineti chamfer is isosceles yekona yekona yakaumbwa uye inogona kuendeswa mune akati wandei akasiyana magineti padivi rimwechete, mativi maviri kana hypotenuse pazere 100% kureba kana kungoita 50% yehurefu.

1. Easy kushanda

2. Reusable uye yakasimba kuderedza mari yakagovaniswa munguva refu

3. Hapana screws, mabhaudhi, welding kana magetsi anodiwa kuti asungirire iyo magnetic chamfer. Kurumidza kuisa, kubvisa uye kuchenesa

4. Universal ine akawanda precast kongiri masisitimu ekudzikisa kuwanda kutenga uye mutengo kune akasiyana masisitimu

5. Yakanyanya kusimba simba rekunamira uye hupenyu hurefu hwebasa kupfuura chamfer yerabha

6. Kuvandudza mhedzisiro yemhando pane precast kongiri zvigadzirwa kuti zvibvise matambudziko mazhinji ekupera kwekuvaka

1. Isingaenzaniswi yemakwikwi esimba remagineti uye kushandiswa muprecast kongiri indasitiri uye kujairana nei uye sei kuita simbi yemagineti chamfers,kuvhara maginetiuye isa magineti kugadzirisa zvinonetsa vatengi

2. Mamwe saizi aripo kuchengetedza mutengo wekushandisa uyezve mutengo wechigadzirwa kune vatengi

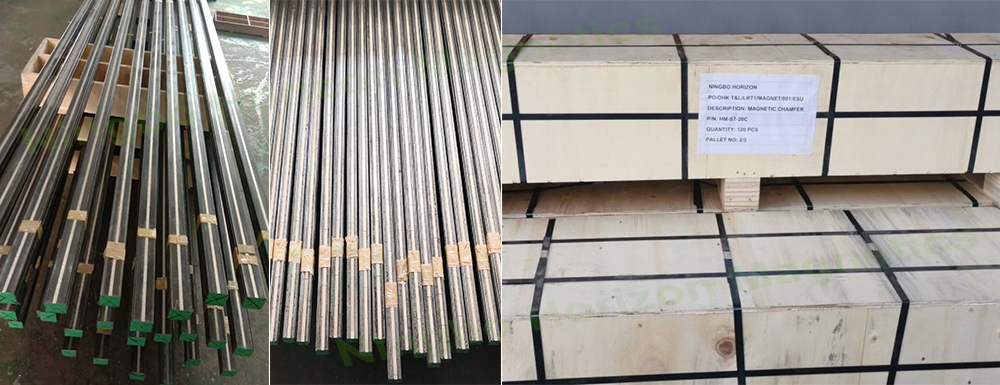

3. Yakajairwa saizi mustock uye inowanikwa kuti iendeswe nekukurumidza

4. Tsika-yakagadzirwa mhinduro dzinowanikwa pakukumbira

5. Magineti mazhinji machamfer anozivikanwa nevatengi uye mamwe emhando dzedu dzinozivikanwa seyakajairwa dhizaini kana saizi mu precast kongiri indasitiri.

| Chikamu Nhamba | A | B | C | Urefu | Kureba kweMagineti | Rudzi rweMagnetized Side | Maximum Operating Temperature | |

| mm | mm | mm | mm | °C | °F | |||

| HM-ST-10A | 10 | 10 | 14 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-10B | 10 | 10 | 14 | 3000 | 50% kana 100% | Kaviri | 80 | 176 |

| HM-ST-10C | 10 | 10 | 14 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-15A | 15 | 15 | 21 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-15B | 15 | 15 | 21 | 3000 | 50% kana 100% | Kaviri | 80 | 176 |

| HM-ST-15C | 15 | 15 | 21 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-20A | 20 | 20 | 28 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-20B | 20 | 20 | 28 | 3000 | 50% kana 100% | Kaviri | 80 | 176 |

| HM-ST-20C | 20 | 20 | 28 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-25A | 25 | 25 | 35 | 3000 | 50% kana 100% | Single | 80 | 176 |

| HM-ST-25B | 25 | 25 | 35 | 3000 | 50% kana 100% | Kaviri | 80 | 176 |

1. Isa magineti chamfer pane formworks zvinyoro nyoro kuitira kudzivirira magineti akakuvadzwa nekukasira kukwezva.

2. Magineti eNeodymium akaiswa anofanira kugara akachena. Dzivisa grout kuvhara magineti kuitira kuchengetedza magineti simba.

3. Kana wapedza kushandiswa, unofanira kuchengetwa wakachena uye kuzorwa mafuta kuitira kuti usaora.

4. Iyo huru yekushanda kana kuchengetedza tembiricha inofanira kunge iri pasi pe80 ℃. Tembiricha yepamusoro inogona kukonzera magineti chamfer kudzikisa kana kurasikirwa zvachose nemagineti.

5. Kunyange zvazvo simba remagineti remagineti simbi yetriangle chamfer yakadzikira pane inovharisa magineti, ichiri yakasimba zvakakwana kugadzira njodzi kuvashandi kuburikidza nekutsikirira pakubata. Kupfeka magirovhosi kudzivirira maoko ako kunokurudzirwa zvikuru. Ndokumbira uichengetedze kure nemidziyo yemagetsi uye zvisina kufanira ferromagnetic simbi. Kuchenjerera kwakanyanya kunofanirwa kuitwa kana munhu akapfeka pacemaker, nekuti magineti akasimba anogona kukuvadza zvemagetsi mukati me pacemaker.